FEATURE

Lot Traceability

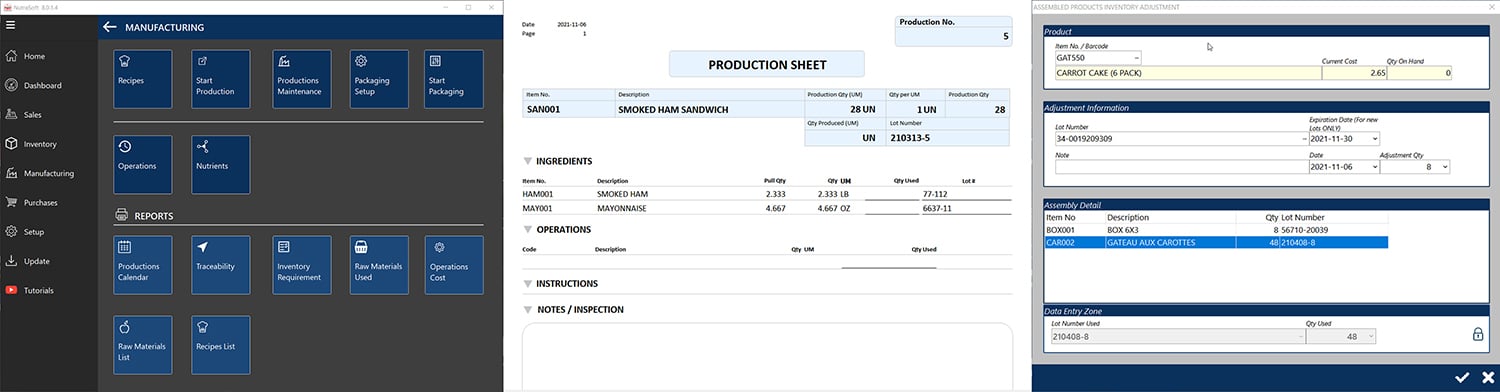

Tired of tracking lots manually? Nutrasoft’s lot tracking system automatically tracks all inventory lot numbers from the moment you buy to the moment you sell. Lot numbers can be tracked on ANY item, from raw materials to packaging to assembled products

Recall, audit or inspect at the push of a button

Now, you won’t have to worry about missing an important lot number or transaction during your next audit or compliance inspection. NutraSoft will automatically alert you whenever a lot is not entered, whether this happens during the purchasing, sales, production or packaging process

Produce customized inventory picklists matching your existing production process. Add photos, PDFs and/or barcodes to make your production process easier than ever.

Be ready for inspection and recall at anytime

Intuitive Lot-Coded Inventory Control

- End-to-end traceability on all materials, inventory & products with batch tracking

- Identify, trace and recall faulty batches, products & raw materials for effective quality assurance and recalls

- Auto-generate internal barcodes & batch numbers

- Track expiry dates of all inventory items

- Produce inventory picklists based on lot numbers and expiry dates

NutraSoft will drastically reduce your workload when it comes to managing and inspecting lots from purchase to sale. As a whole, NutraSoft is designed to make your life easier by allowing you to mold the software as closely as possible to your current operations and habits.

Production Planning

Plan your productions and, if possible, schedule which inventory lots you plan to use in advance, if not, you can select lots during the production or after the production has been completed.

Packaging

Customize your packaging process by creating multiple package configurations for each recipe. Track and create lot codes throughout that process

Tracking Reports

Easily produce a report during any stage of the lot tracking process

NutraSoft in Action

NutraSoft’s user friendly lot traceability system allows you to easily access every aspect of your daily routine at a push of a button.

- When making a sale, scan or enter the lot codes that you plan to ship into the Nutrasoft sales order and invoicing system. Once complete, lot codes of all products sent out to your customers will be lot-tracked and ready for recall at any moment.

- To issue a recall, simply visit the traceability menu option and select the affected products. A detailed recall report will be created with all the lot codes to be recalled.

So what will your day to day of Lot Traceability look like while using NutraSoft?

- Scan or add inventory items and lot codes into stock as you receive shipments. If the shipment doesn’t have a scannable lot code, you can also enter the lot code manually after you scan the item. Each lot code will be automatically stored in the inventory system.

- When production planning, a production lot code will be automatically generated and attributed to that production process. It is also possible to change this lot code to replace it with your own. Inventory lot codes used in the production process can be scanned or entered manually before, during or after production.

- When scheduling the packaging process, a package lot code will be automatically generated and attributed to the process. This lot code can be changed to conform to your existing lot code system. The batch lot codes used in the packaging process can be scanned or entered manually before, during or after the packaging process.

Book a Demo

One of our associates will be more than happy to book a demonstration at your best convinience